Food manufacturers today face constant pressure to do more with less—improve yield, reduce waste, ensure traceability, and scale across multiple facilities. But without the right digital infrastructure in place, these goals are difficult to achieve. That’s where MES and MOM come into play.

In this post, we’ll explain the difference between Manufacturing Execution Systems (MES) and Manufacturing Operations Management (MOM)—and why this distinction matters for companies looking to modernize.

We’ll also introduce a free white paper that outlines a proven methodology for implementing MES in food production and showcases real-world results from Cargill and Gedik Piliç.

2 min read

What Is the Difference Between MES and MOM in Food Manufacturing?

By Kathy Barbeire on May 13, 2025 10:28:29 AM

Topics: food traceability food manufacturing software manufacturing execution system yield optimization in food production MES vs MOM digital transformation in food processing erp integration in food manufacturing

2 min read

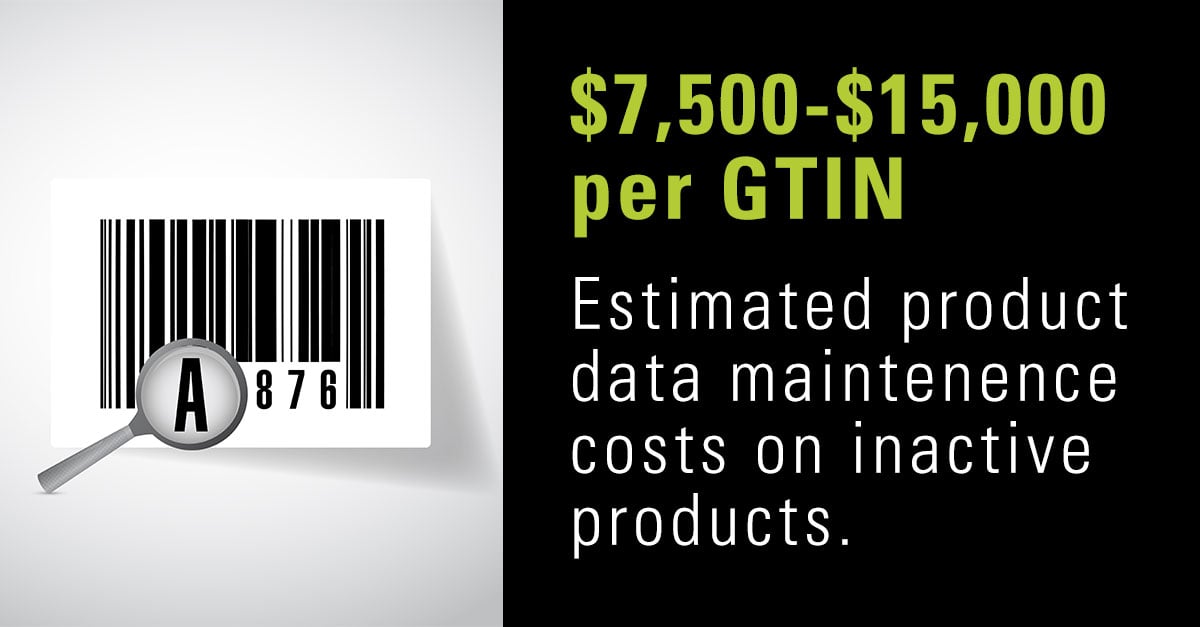

CASE STUDY: Improved Data Quality Saves $ Millions

By Kathy Barbeire on May 19, 2023 12:07:01 AM

A case study coauthored by GS1 US and Nestlé Professional demonstrates that good data governance saves time and money while providing transparency and trust to the customers.

Topics: food traceability GS1 Standards data quality management

1 min read

Fieldale Farms Implements RFID Technology to Enhance Traceability

By Kathy Barbeire on May 3, 2023 11:42:55 AM

In 2022, Fieldale Farms received a customer request to implement new traceability requirements. The customer’s goal was to increase traceability transparency for their consumers, eliminate manual scanning at all levels of their supply chain, improve their inventory accuracies, and build consumer trust. Fieldale brought in CAT Squared to build seamless integrations between the traceability platform and plant-floor hardware to meet the customer’s request.

"CAT Squared helped us achieve the goals our customer asked for by providing new developments in RFID technology systems," said Cameron Smith, IT plant liaison at Fieldale Farms Corporation. Because CAT Squared’s plant-floor solutions are hardware- and software-agnostic, the team was easily able to integrate with readers from Zebra Technologies, software from Mojix, and labeling systems from Avery Dennison.

The customer’s RFID program required Fieldale to incorporate label attributes that comply with the GS1 Foodservice traceability program. The GS1-128 barcodes are scanned throughout the supply chain, capturing the physical location and context of specific products, their lot numbers, production dates, and expiration dates. RFIDs rely on the serialization of each case and linking that serial number to a product commissioning event.

To meet that requirement, CAT Squared handled the encoding (and decoding) of serials to SGTIN-96 (Serialized Global Trade Identification Number) for creating the RFID labels. The system then transmitted Fieldale’s production data by product to Mojix for commissioning events.

In addition to meeting their customer’s requirements, the RFID initiative is anticipated to save Fieldale time on inventory management and stock rotation, mitigate human error, and increase expiration date visibility. Ultimately, the goal is to create a more transparent supply chain through a best-in-class traceability system to enable safety, efficiency, and the verification of food with integrity.

Topics: Traceability technology food traceability GS1 Standards

4 min read

Are Meat Processors Prepared for the Extinction of the UPC Barcode?

By Sheridan Brewer on Apr 5, 2022 5:19:30 PM

By 2027, retailers must be able to scan a 2D barcode to retrieve the GTIN-12 (UPC) data string in addition to the linear, 1D EAN/UPC barcode that is commonly used today for pricing information at checkout. This does not mean the linear UPC barcode will go away entirely, but product suppliers will be able to choose between using a 2D barcode or both barcodes on their POS items.

The rollout of the 2D barcode requirement is supported through Sunrise 2027, a new initiative from GS1 US – a neutral, not-for-profit organization that develops internationally recognizable supply chain standards.

Topics: food traceability supply chain software labeling system weigh and label system inventory accuracy waste prevention

2 min read

5 Steps for Food Suppliers to Adopt Digital Supply Chain Technology

By Kathy Barbeire on Jan 8, 2021 4:01:46 PM

This last year revealed many vulnerabilities and challenges for food suppliers. The pandemic exposed a vulnerability in manufacturers’ reliance on human labor. Regulatory bodies like the FDA, USDA, and GFFA are compelling supply-chain participants to adopt common standards and digital technologies. Retailers – who are under pressure from consumers demanding more variety, sustainability, transparency, and ethical sourcing – are increasingly willing to go around manufacturers to create the products they need if they can’t get the relationship they want with the manufacturer. These challenges will continue beyond 2021.

Topics: Traceability technology supply chain food traceability continuous improvement key data elements manufacturing automation critical tracking events GS1 Standards

1 min read

CAT Squared Releases New Android Apps

By Kathy Barbeire on Mar 12, 2020 2:00:05 PM

In January 2020, Microsoft officially ended its support for Windows Embedded Handheld 6.5. This will complete the end-of-life process for all Windows ruggedized environments.

Topics: food traceability android mobile handheld warehouse management software wms software warehouse management system inventory management system barcode scanners

6 min read

How Technology and Consumers are Transforming the Food Value Chain

By Kathy Barbeire on Feb 11, 2020 5:15:39 PM

At Purdue University's National Conference for Food and Agribusiness, speakers presented results of the University’s research study analyzing what data is collected across the food value chain, how it’s shared, and to what extent it is used to make strategic decisions. The study focused on five levels of the value chain: (1) Ag Input Manufacturers, (2) Ag Retailers, (3) Farmers, (4) First Handlers/Food Processors, (5) Food Manufacturers, and (6) Food Retailers. The event included panel discussions with representatives from each part of the value chain discussing trends they’re experiencing.

Topics: Traceability technology supply chain food traceability technology adoption manufacturing technology food manufacturing automation regulatory compliance food value chain consumer demand

2 min read

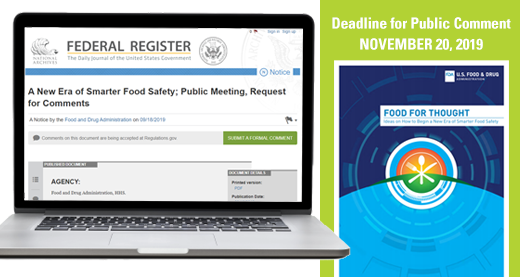

Leading in 'A New Era of Smarter Food Safety'

By Kathy Barbeire on Nov 12, 2019 7:27:50 PM

On October 21, 2019, the FDA held a public meeting with a broad cross-section of industry stakeholders to build a shared vision around A New Era of Smarter Food Safety, a campaign intended to strengthen the agency’s protection of the food supply.

Topics: Era Smarter Food Safety blockchain Traceability technology food traceability supply chain software prescriptive analytics food manufacturing AI industrial internet of things

1 min read

Blockchain Conference Yields Benefits beyond Traceability

By Kathy Barbeire on Apr 17, 2019 2:49:47 PM

On March 29, members of the CAT Squared team attended the 2019 Blockchain Conference hosted by the Center for Blockchain Excellence at the University of Arkansas Sam M. Walton College of Business. The conference included several keynote speakers including Arkansas Governor Asa Hutchinson and FDA Deputy Commissioner for Food Policy and Response Frank Yiannas. There were also breakout sessions with panels of blockchain innovators and opportunities for developers to break out their laptops and practice interacting with blockchain development platforms. However, of all the sessions we attended, the one I found most exciting was a discussion led by Golden State Foods (GSF) Chief Technology Officer Guilda Javaheri.

Topics: blockchain Traceability technology supply chain food traceability food manufacturing automation food manufacturing AI

1 min read

CAT Squared to Develop Blockchain App Connecting the Food Value Chain

By Kathy Barbeire on Apr 9, 2019 6:25:08 PM

For nearly 25 years, CAT Squared has developed manufacturing execution systems (MES) to manage plant-floor processes for food processing facilities. CAT Squared’s MES delivers end-to-end traceability from receiving of ingredients and dry goods through shipping of final product. By combining our MES with blockchain and other IIoT technologies, CAT Squared can now expand the reach of our capabilities outside the four walls of the plant, connecting all participants of the food value chain.