This World Quality Week 2025, we’re embracing the theme “Quality: Think Differently.” In food manufacturing, that means reimagining quality not as a reactive function managed by QA, but as a living culture owned by everyone—from operators to executives.

Recent posts by Kathy Barbeire

6 min read

Think Differently about Quality in Food Manufacturing

By Kathy Barbeire on Nov 11, 2025 1:36:52 PM

1 min read

SAVE THE DATE: CAT² User Summit 2026

By Kathy Barbeire on Aug 18, 2025 5:27:09 PM

We’re excited to invite you to the CAT Squared User Summit 2026, hosted at the beautiful Oaklawn Racing Casino Resort in Hot Springs, Arkansas.

2 min read

CMI Leverages CYNERGY MES for Smart Poultry Processing and Yield Optimization

By Kathy Barbeire on Aug 8, 2025 6:54:26 PM

CAT Squared is now the MES of choice for three of the top five poultry companies in LATAM — Cargill, Bachoco, and CMI — with 32 plants across the region running our system.

7 min read

Beyond ERP - Part 3: MES + ERP = Real ROI in Food Manufacturing

By Kathy Barbeire on Jul 11, 2025 5:58:17 PM

Previously in our Beyond ERP series, we saw how an MES complements an ERP by managing plant-floor operations in detail. But what does this mean for your bottom line and overall performance? In this final part of our series, we focus on the business benefits of combining ERP with a Manufacturing Execution System – specifically, how this “execution layer” drives end-to-end traceability, enables ongoing continuous improvement, and ultimately delivers a compelling Return on Investment (ROI). We’ll also share real-world examples demonstrating the value of MES software for food manufacturing.

Topics: MES vs ERP erp integration in food manufacturing erp limitations food manufacturing mes

4 min read

Beyond ERP — Part 2: Bridging the Execution Gap in Food Manufacturing

By Kathy Barbeire on Jun 17, 2025 4:53:32 PM

In Part 1 of our Beyond ERP series, we explored why traditional ERP platforms struggle with the realities of food manufacturing. Now, let’s focus on the solution: a Manufacturing Execution System (MES).

A food-industry MES is purpose-built to manage and record what happens on the factory floor in real time. It doesn’t replace your ERP — it enhances it. With an MES, meat and poultry processors gain control over disassembly, yield tracking, traceability, and execution.

Topics: MES vs ERP erp integration in food manufacturing erp limitations food manufacturing mes

3 min read

Beyond ERP — PART 1: Managing Plant-Floor Operations in Food Manufacturing

By Kathy Barbeire on Jun 10, 2025 5:11:22 PM

Enterprise Resource Planning (ERP) systems are essential for food manufacturers, providing centralized control over finance, procurement, and inventory management. But when it comes to plant-floor execution, especially in meat and poultry operations, ERP alone often isn’t enough.

In this first post of our Beyond ERP blog series, we break down the limits of ERP in food manufacturing and introduce the processes where an MES (Manufacturing Execution System) outperforms ERP—particularly in disassembly, reassembly, mixing, traceability, and yield tracking.

Topics: erp limitations food manufacturing mes

3 min read

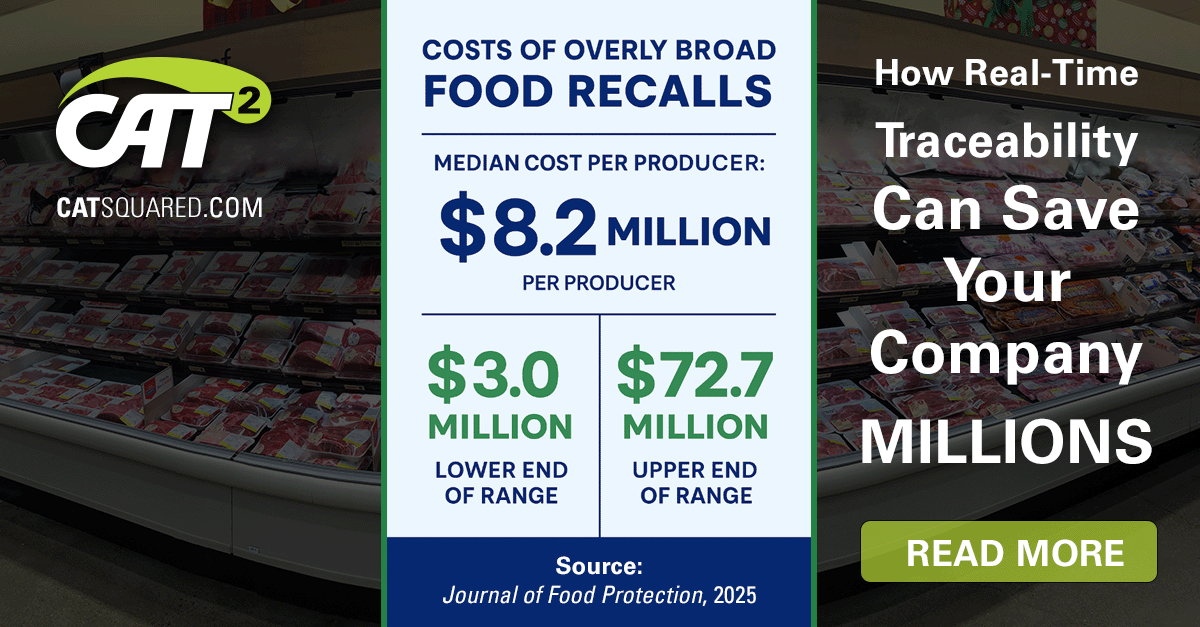

How Real-Time Traceability Software Reduces the Cost and Scope of Food Recalls

By Kathy Barbeire on May 20, 2025 1:10:49 PM

When a food recall happens, the damage is rarely limited to just the affected products. In many cases, the entire production run—or even multiple lots—gets pulled from the market because companies can’t pinpoint the exact scope of contamination.

Topics: real-time traceability software food recall mitigation tools kde and cte traceability reduce scope of food recall food traceability ROI precision food traceability recall cost food industry

3 min read

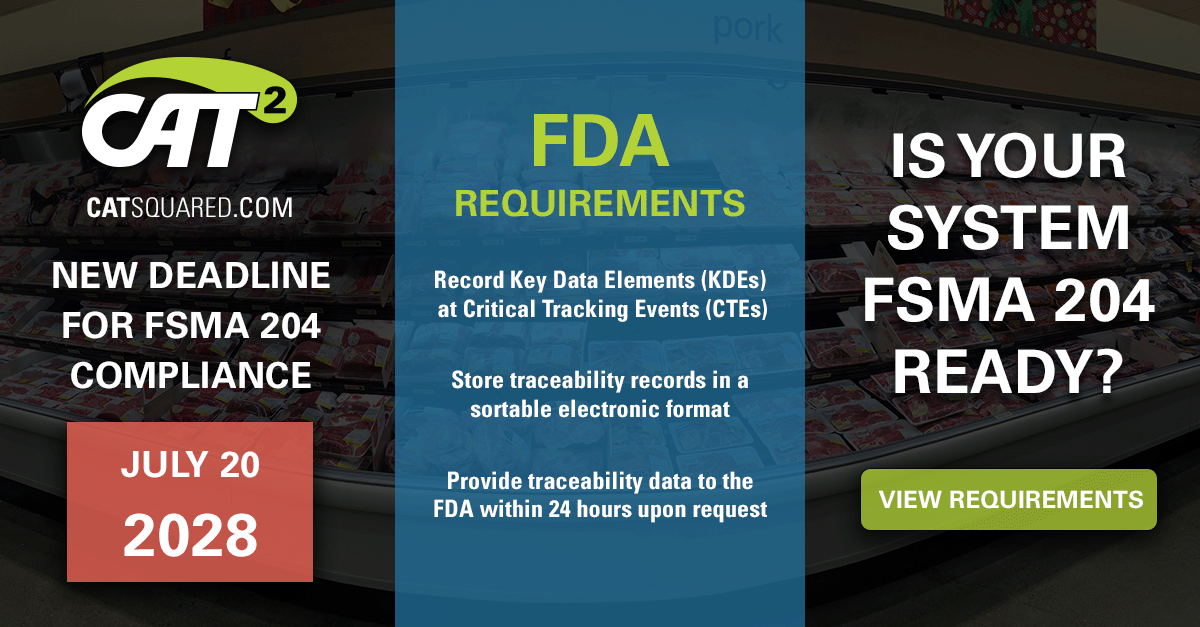

FSMA 204 Traceability Software: Going Beyond Basic Compliance

By Kathy Barbeire on May 16, 2025 4:56:59 PM

FSMA 204 is changing how food manufacturers approach traceability. Under the new rule, certain foods on the FDA's Food Traceability List (FTL) require more robust tracking, including documentation of Key Data Elements (KDEs) and Critical Tracking Events (CTEs). But simply meeting the minimum requirements isn’t enough to protect your business.

Topics: food traceability solutions traceability software for food processors fsma 204 traceability kde cte compliance recall prevention food industry

2 min read

What Is the Difference Between MES and MOM in Food Manufacturing?

By Kathy Barbeire on May 13, 2025 10:28:29 AM

Food manufacturers today face constant pressure to do more with less—improve yield, reduce waste, ensure traceability, and scale across multiple facilities. But without the right digital infrastructure in place, these goals are difficult to achieve. That’s where MES and MOM come into play.

In this post, we’ll explain the difference between Manufacturing Execution Systems (MES) and Manufacturing Operations Management (MOM)—and why this distinction matters for companies looking to modernize.

We’ll also introduce a free white paper that outlines a proven methodology for implementing MES in food production and showcases real-world results from Cargill and Gedik Piliç.

Topics: food traceability food manufacturing software manufacturing execution system yield optimization in food production MES vs MOM digital transformation in food processing erp integration in food manufacturing

2 min read

Best Handheld Scanner for Food Manufacturing? Why CAT Squared Recommends the Keyence BT-A600

By Kathy Barbeire on May 6, 2025 5:17:25 PM

Food manufacturing environments demand barcode scanners that can withstand cold storage, handle high-speed workflows, and integrate seamlessly with MES and ERP systems. The Keyence BT-A600 is the newest device we’ve tested and now officially recommend for customers using CAT Squared’s MES platform. Here’s why it stands out.