At CAT Squared, we’ve built our reputation on delivering powerful MES software tailored to the needs of food manufacturers. But behind the scenes, we’ve always done more—testing, configuring, and supporting the hardware that keeps plant-floor systems running.

Now, we’re making our hardware recommendations official to better support MES and ERP integration in food production environments.

Recent posts by Kathy Barbeire

1 min read

CAT Squared’s Hardware Picks for Seamless MES & ERP Integration

By Kathy Barbeire on May 6, 2025 5:13:53 PM

4 min read

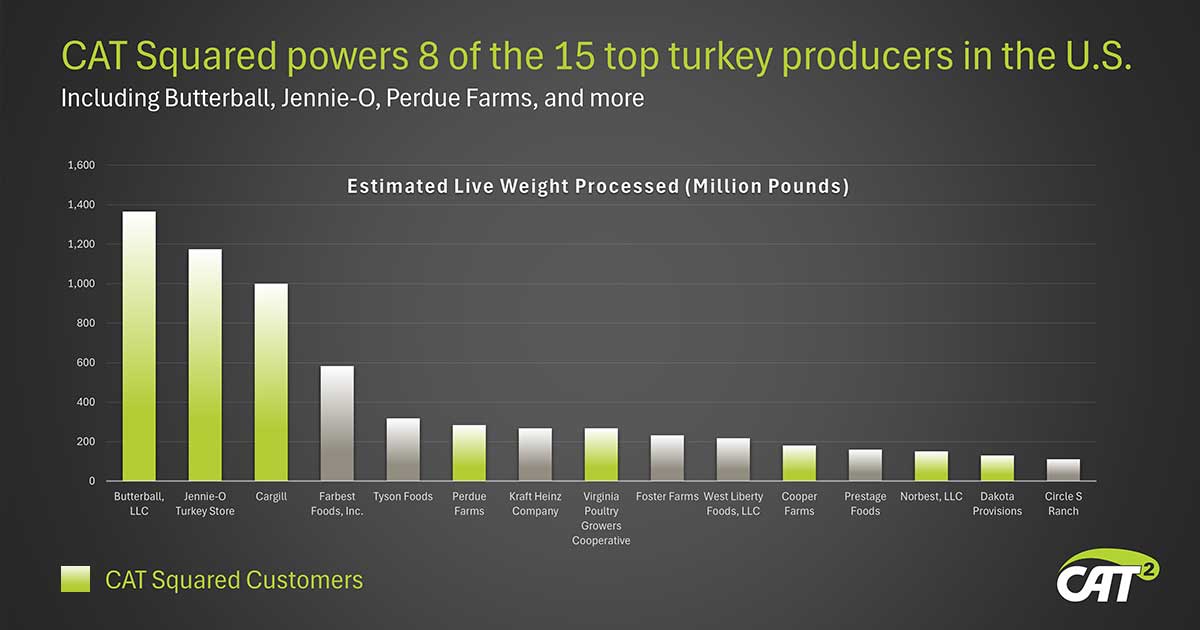

Why 8 of the Top 15 U.S. Turkey Producers Trust CAT Squared software

By Kathy Barbeire on Apr 29, 2025 5:34:12 PM

Profitability in turkey processing often depends on a few critical factors: reducing downtime, increasing line efficiency, maximizing yield, and minimizing giveaway. That’s why leading poultry processors trust CAT Squared software to tackle the unique challenges of poultry production and deliver measurable results.

Topics: manufacturing execution system Turkey producers turkey processing MES poultry industry software food production MES

5 min read

What Food Manufacturers Get Wrong About Automation

By Kathy Barbeire on Apr 3, 2025 11:37:28 PM

In the race to modernize operations, many food manufacturers equate automation with hardware. They invest in robotic arms, automated conveyors, and high-speed packaging systems — expecting a fast return on investment through increased output and reduced labor.

Topics: food manufacturing automation manufacturing execution system food processing software increase plant efficiency yield optimization in food production MES vs ERP real-time plant monitoring

2 min read

CAT Squared to showcase the only end-to-end MES for the food industry at Anuga FoodTec

By Kathy Barbeire on Feb 27, 2024 12:14:39 PM

CAT Squared, a leading global provider of software solutions for the food industry, is pleased to demonstrate the capabilities of the only end-to-end MES for the food industry at Anuga FoodTec in Cologne, Germany. This event marks the company's first appearance at one of the prominent international trade fairs dedicated to food technology and innovation.

Topics: food processing continuous improvement industry 4.0

2 min read

CAT Squared Joins CTB Sister Companies to Present CYNERGY™: Advancing Poultry Processing at IPPE

By Kathy Barbeire on Dec 29, 2023 1:01:01 PM

CAT Squared, a trusted provider of advanced software solutions for the food processing industry, collaborates with CTB sister companies Chore-Time, Meyn, and Cabinplant to unveil CYNERGY™ at the International Production & Processing Expo (IPPE) from January 30 to February 1, 2024, in Atlanta, Georgia.

Topics: poultry industry continuous improvement industry 4.0

2 min read

CAT Squared and Meyn Debut CYNERGY at Alimentaria FoodTech 2023

By Kathy Barbeire on Oct 23, 2023 2:51:26 PM

BARCELONA, SPAIN — Alimentaria FoodTech 2023 witnessed the impressive showcase of CYNERGY™, a collaborative effort between CAT Squared and Meyn. While Meyn's expertise primarily focuses on first processing in poultry production, CAT Squared's MES software solution covers a broader spectrum of functionalities: managing first processing, secondary processing, and further processing in meat, poultry, and RTC/RTE (ready-to-cook/ready-to-eat) food production.

3 min read

CAT Squared Supports Meat Industry Sustainability through Protein PACT Partnership

By Kathy Barbeire on Oct 6, 2023 12:46:29 PM

The release of the Protein PACT's 2023 Continuous Improvement Report marks a significant milestone in the ongoing journey toward sustainability within the meat industry. It's a testament to the collective efforts of industry leaders, and CAT Squared is proud to play a key supportive role in these transformative endeavors.

Topics: meat industry poultry industry continuous improvement sustainability Protein PACT

2 min read

CAT Squared Exhibiting at the 2023 Poultry Symposium for Production & Processing

By Kathy Barbeire on Aug 25, 2023 3:10:55 PM

The countdown has begun for the 2023 Poultry Symposium for Production & Processing, set to take place from October 9 to 11, 2023, at the Rogers Convention Center in Rogers, AR. You can find CAT Squared at booth 21. We are excited to connect with industry peers, showcase our solutions, and discuss the latest developments in poultry processing technology.

2 min read

CAT Squared: Paving the Way for Sustainability at the Protein PACT Summit 2023

By Kathy Barbeire on Aug 25, 2023 12:33:10 PM

In an era defined by transformative change and unwavering sustainability commitments, the meat industry stands at a crossroads of innovation, responsibility, and progress. CAT Squared proudly announces its sponsorship of the North American Meat Institute's (NAMI) 2023 Protein PACT (People, Animals, Climate of Tomorrow) Summit, a dynamic event that crystallizes the collective determination to shape a responsible and sustainable future for the industry.

Topics: meat industry poultry industry continuous improvement sustainability Protein PACT

3 min read

CAT Squared and Meyn Unveil CYNERGY Solution at Alimentaria FoodTech

By Kathy Barbeire on Aug 14, 2023 2:53:06 PM

CAT Squared, a leading provider of advanced software solutions for the food industry, and Meyn, a global leader in poultry processing solutions, are proud to announce the joint presentation of their groundbreaking CYNERGY™ solution at Alimentaria FoodTech. The event is scheduled to take place from September 26th to 29th, 2023, at Fira Barcelona - Gran Via in Barcelona, Spain. Industry professionals are invited to experience the future of poultry processing and food production at Booth D82.

CYNERGY™ represents a cutting-edge collaboration between Meyn and CAT Squared, leveraging the strengths of both companies to deliver a comprehensive and intelligent solution that transforms the poultry processing industry. The innovative technology combines Meyn's expertise in poultry processing equipment with CAT Squared's advanced software suite, providing seamless integration and real-time data analysis for enhanced production efficiency and quality control.

At Booth D82, visitors will have the opportunity to explore the following key features of CYNERGY™:

Poultry Processing Excellence: CYNERGY™ showcases Meyn's state-of-the-art poultry processing equipment, renowned for its precision, speed, and reliability. Attendees will witness firsthand how the machinery optimizes the entire processing line, from evisceration and cutting to deboning and portioning.

Real-time Data Insights: CAT Squared's advanced software suite seamlessly integrates with Meyn's processing equipment, offering real-time data insights on key performance indicators. This data-driven approach empowers decision-makers with actionable information to enhance production efficiency, reduce downtime, and minimize waste.

Traceability and Quality Assurance: CYNERGY's farm-to-fork traceability solution, powered by CAT Squared, ensures complete transparency throughout the supply chain. From tracking the origin of raw materials to monitoring quality metrics, food manufacturers gain confidence in delivering safe and traceable products to consumers.

Compliance and Food Safety: With a focus on meeting industry-specific regulations and certifications, CYNERGY™ streamlines compliance management, reducing the risk of food safety incidents and ensuring adherence to international standards.

AI-driven Insights: AI capabilities enabled by the CYNERGY™ Cloud delivers predictive maintenance insights, optimizing equipment performance and prolonging the lifespan of processing machinery.

"We are thrilled to introduce CYNERGY™ at Alimentaria FoodTech," said Vernon Smith, CEO at CAT Squared. "This revolutionary solution represents the convergence of two industry leaders, Meyn and CAT Squared, to redefine the future of poultry processing. CYNERGY™ empowers food manufacturers with a level of automation, efficiency, and data-driven decision-making that sets new industry standards."

"CYNERGY™ is the result of a synergistic collaboration between Meyn and CAT Squared," said Eric-Jan Radstake, Chief Innovation Officer at Meyn. "By combining Meyn's best-in-class poultry processing equipment & software programs with CAT Squared's powerful software suite, we are delivering a solution that not only enhances productivity but also elevates food safety and quality throughout the entire production process."

Don't miss this opportunity to witness the future of poultry processing and food production. Join Meyn and CAT Squared at Booth D82 during Alimentaria FoodTech in Barcelona, Spain, from September 26th to 29th, 2023. Experience CYNERGY™ firsthand and learn how it can transform your poultry processing operations.

CONTACT:

CAT Squared: Guillermo Milman, Technical Sales Manager Iberoamérica, Guillermo.Milman@catsquared.com, +34 635 507 140

MEYN: Albert Ribalta, Commercial Director, Meyn Food Equipment Iberica, aribalta@meyn.com +34 620043209

About Meyn:

Meyn is a leading global supplier of innovative poultry processing solutions, offering a comprehensive range of equipment and services to poultry processors worldwide. With a commitment to excellence, Meyn's cutting-edge technology and reliable machinery set the industry standard, ensuring efficient and high-quality poultry processing operations.

About CAT Squared:

CAT Squared is a trusted provider of advanced software solutions for the food and beverage manufacturing industry. The company's software suite empowers food manufacturers with real-time data insights, traceability solutions, and predictive analytics to optimize production processes, enhance food safety, and ensure compliance with industry standards.