Profitability in turkey processing often depends on a few critical factors: reducing downtime, increasing line efficiency, maximizing yield, and minimizing giveaway. That’s why leading poultry processors trust CAT Squared software to tackle the unique challenges of poultry production and deliver measurable results.

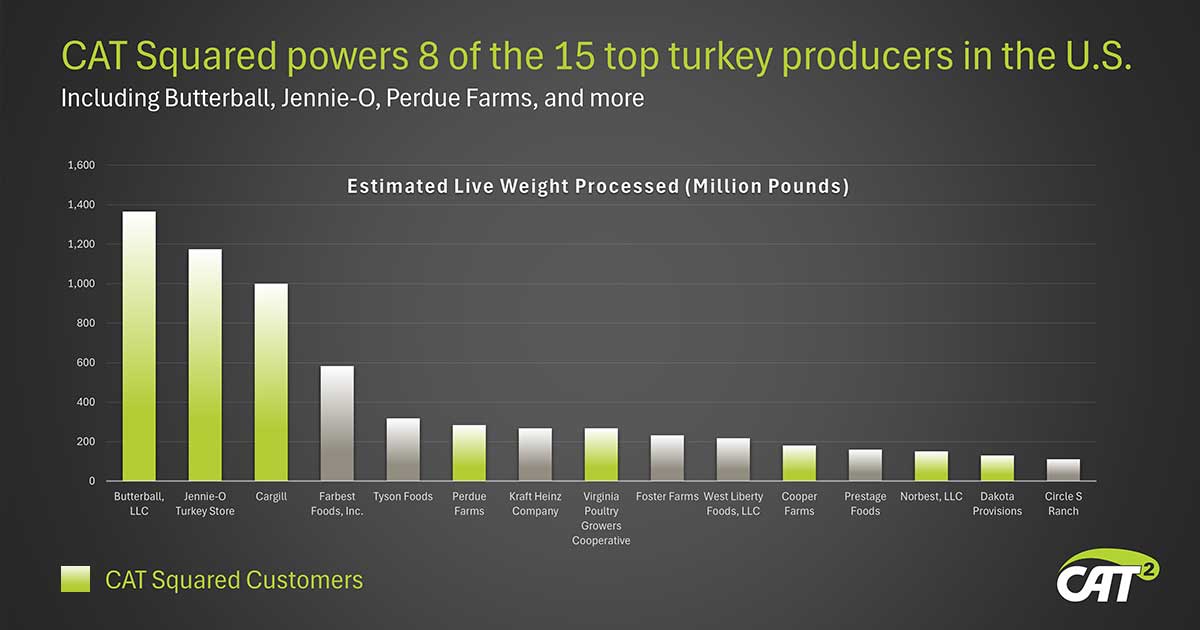

Today, 8 of the top 15 U.S. turkey producers—including Butterball, Jennie-O, Cargill, Perdue Farms, Virginia Poultry Growers Cooperative, Cooper Farms, Norbest (Pitman Farms), and Dakota Provisions—use CAT² solutions to support their operations.

Whether it’s our Laboratory Information Management System (LIMS), Food Safety & Quality Management (FSQM) applications, or our broader CYNERGY™ MES platform, processors count on CAT² for accurate data, real-time visibility, and continuous improvement.

Built for the Complexities of Turkey Processing

Our CYNERGY™ platform is designed for producers seeking turkey processing software that adapts to real-world challenges—managing bird-size variability, improving poultry yield management, reducing waste, and boosting operational efficiency.

Unlike broilers, turkeys vary significantly in size and quality, introducing complexity to primary poultry processing. Managing this variability is essential for optimizing equipment settings, maintaining throughput, and protecting margins. CAT² solutions provide:

- Real-time visibility into flock and plant performance

- Quality management tools to enforce regulatory standards and customer product specifications

- Yield and efficiency reporting to pinpoint losses

- Data governance to ensure consistency across multiple facilities.

"CAT Squared is the best system for our industry. I’ve used CAT Squared in our production plant for years, and there is nothing else on the market that is better aligned with our production processes."

— Lee Simonsen, IT Director at Turkey Valley Farms

Smarter Grower and Flock Management

Our platform enables processors to build detailed grower performance profiles and monitor flock trends across farms and seasons. This provides the tools needed to:

- Proactively adjust processes to incoming bird size and quality

- Optimize equipment settings for varying flock profiles

- Rank and reward growers based on yield, quality, and performance

- Identify underperforming flocks to reduce risk and loss

Year-over-year data helps manage seasonality, disease risk, and flock variability—leading to smarter production decisions and higher profits.

Digital Defect Management and Quality Control

Our poultry MES system provides real-time dashboards for monitoring poultry yield KPIs across slaughter, evisceration, chilling, and beyond. With real-time defect tracking, processors can identify quality issues immediately, reducing rework, improving product consistency, and maintaining regulatory compliance.

CAT² quality and food safety tools empower plants to:

- Digitize inspections and audits

- Monitor defects in real time

- Ensure compliance with regulatory requirements

- Enforce customer product specifications to maintain brand trust and satisfaction.

Explore more in our blog: Maximizing Efficiency with Manufacturing Software.

Seamless Integration with Poultry Plant Equipment

As a hardware-agnostic platform, CAT Squared integrates easily with existing poultry plant equipment. This ensures seamless data capture, reduces implementation time, and protects existing technology investments.

From kill schedule tracking to real-time production yield reporting, CAT Squared equips plant managers with:

- Insights to reduce downtime

- Tools to optimize throughput and labor

- Alerts to minimize rework and giveaway

- Executive dashboards for plant-wide performance visibility

Real-Time Poultry Processing Data for Smarter Decision-Making

With CYNERGY’s real-time poultry data analytics, processors can:

- Maximize yield and minimize waste

- Improve order fulfillment rates

- Reduce giveaway

- Deliver consistent product quality

- Support continuous improvement across operations

Actionable reporting transforms raw data into strategic insights that protect margins and drive growth.

How Poultry Yield Reporting Powers Profitable Turkey Processing

CYNERGY™ yield reporting transforms operational data into action. Key metrics include:

- Live Shrink: Monitoring bird weight loss from farm to plant.

- Dead-on-Arrival (DOA) Rate: Ensuring animal welfare and early identification of transport issues.

- Condemnation Rates by Cause: Linking yield loss directly to flock and grower performance.

- Processing Yield by Stage: Identifying where yield losses occur in slaughter, evisceration, and chilling.

- Cost per Pound of Yield: Providing a full view of production costs and profitability.

Configurable alerts and executive dashboards enable rapid response and continuous optimization—driving a culture of continuous improvement and long-term gains in yield, efficiency, and profitability.

Learn more about our approach in our CYNERGY First Processing White Paper.

Ready to Improve Your Poultry Processing Yields?

Discover how CAT Squared’s turkey processing software and poultry MES solutions can help your operation maximize yield, improve efficiency, and increase profitability.

Schedule a Demo to learn more.