FSMA 204 is changing how food manufacturers approach traceability. Under the new rule, certain foods on the FDA's Food Traceability List (FTL) require more robust tracking, including documentation of Key Data Elements (KDEs) and Critical Tracking Events (CTEs). But simply meeting the minimum requirements isn’t enough to protect your business.

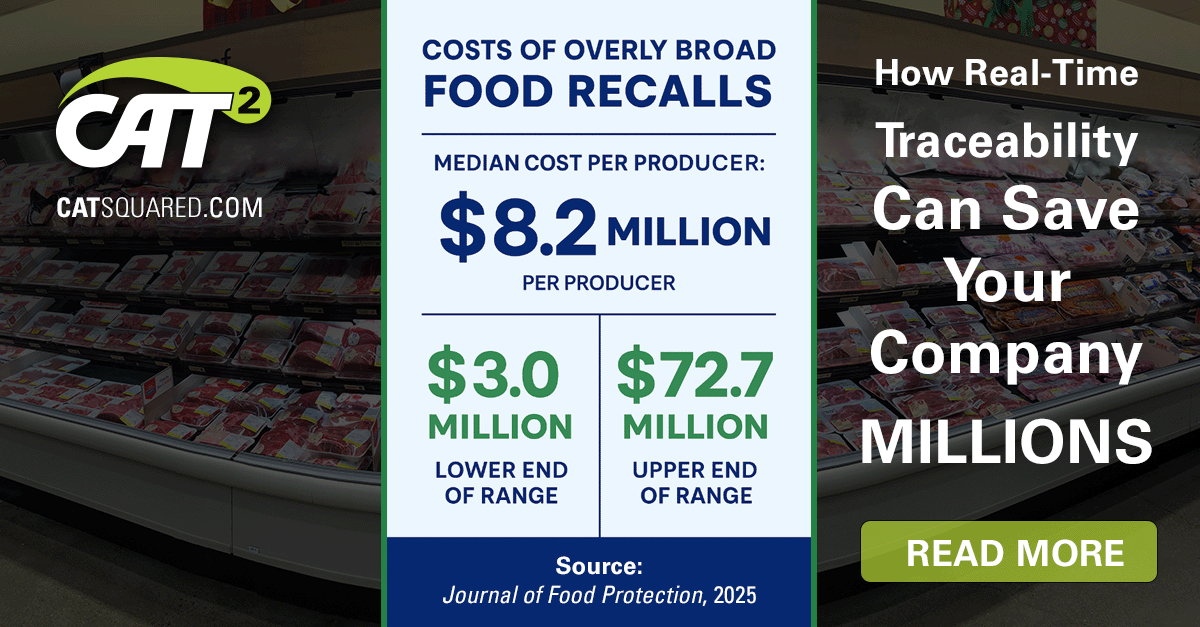

The real risk isn’t noncompliance—it’s issuing an overly broad recall because you can’t isolate affected lots.

According to a peer-reviewed study published in the Journal of Food Protection, the median cost of an overly broad recall is $8.2 million per producer, with some exceeding $72.7 million. These costs come from unnecessary product disposal, legal liabilities, logistics, and reputational damage.

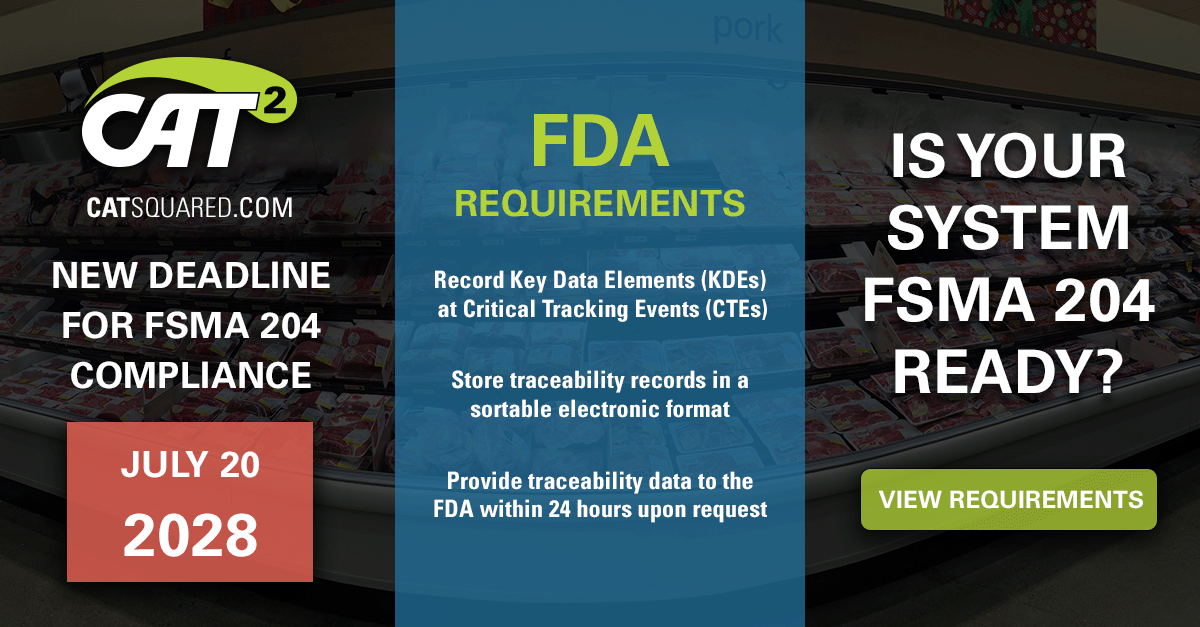

What Does FSMA 204 Require?

FSMA 204 mandates that companies:

-

Capture KDEs at each CTE for foods on the FDA’s Traceability List

-

Maintain records in a sortable, electronic format

-

Provide these records to the FDA within 24 hours of a request

While FSMA 204 applies to a specific list of foods, the need for precise traceability applies across the entire food industry.

One-Up, One-Down: The Regulatory Baseline

CAT Squared’s core MES platform already supports the one-up, one-down traceability model required under current USDA and FDA regulations. Our system links supplier data with outbound shipments, capturing key traceability data from live receiving through processing, labeling, warehousing, and shipping.

For many processors, this foundation meets existing regulatory needs—but CAT Squared goes further.

Going Beyond FSMA 204 with Integrated, Real-Time Traceability

Our Starfish-powered traceability engine captures KDEs, CTEs, quality records, and supplier certifications in real-time, seamlessly integrated with your production and warehouse data.

With CAT Squared, food processors can:

-

Capture real-time data at each CTE

-

Generate FDA-ready reports within minutes

-

Isolate affected lots without pulling unaffected product

-

Respond faster and more precisely in crisis events

-

Support retailer requests with interoperable, EDI-friendly formats

The Strategic Value of Compliance

FSMA 204 compliance shouldn’t be a burden—it should be a business advantage. With the right systems in place, traceability becomes a tool for:

-

Reducing the cost and scope of recalls

-

Minimizing unnecessary product waste

-

Strengthening retailer and regulator relationships

-

Supporting ESG and transparency initiatives

Future-Proof Your Traceability Strategy

Regulations will continue to evolve, and consumer expectations around transparency and safety will only increase. CAT Squared’s traceability solutions ensure you’re not only compliant today—but prepared for tomorrow.

Want to learn how our traceability solutions can reduce your recall risk? Explore our platform.

Looking for real-world strategies to reduce recall risk?

👉 Read: How Real-Time Traceability Software Reduces the Cost and Scope of Food Recalls

Want to know more about how to prep for compliance?

👉 Check out: FSMA 204 Traceability Requirements: What Food Processors Need to Know