If you’re a protein processor that has yet to take a significant step into the world of Industry 4.0, you're not alone. Globally, 90 percent of manufacturing companies are Digital Novices, Followers, or Innovators, and less than one-third are well-advanced on their digital journey. If you are just starting out, here are five practical steps to help meat and poultry processors improve manufacturing performance by digitizing their plant floor operations with Industry 4.0 technology.

What is Industry 4.0?

Industry 4.0 incorporates a range of technologies and processes that include:

- IIoT (Industrial Internet of Things) sensors collecting data on the production line.

- Plantwide networks feeding that data through advanced PLCs (Programmable Logic Controller) and the MES (Manufacturing Execution System).

- IT technologies to then analyze that data using advanced AI and prescriptive analytics capabilities.

Because of the breadth of technologies and processes that can be involved, not every business will be using Industry 4.0 to the same level of sophistication, while still being undeniably Industry 4.0-focused.

Beginning the Digital Journey

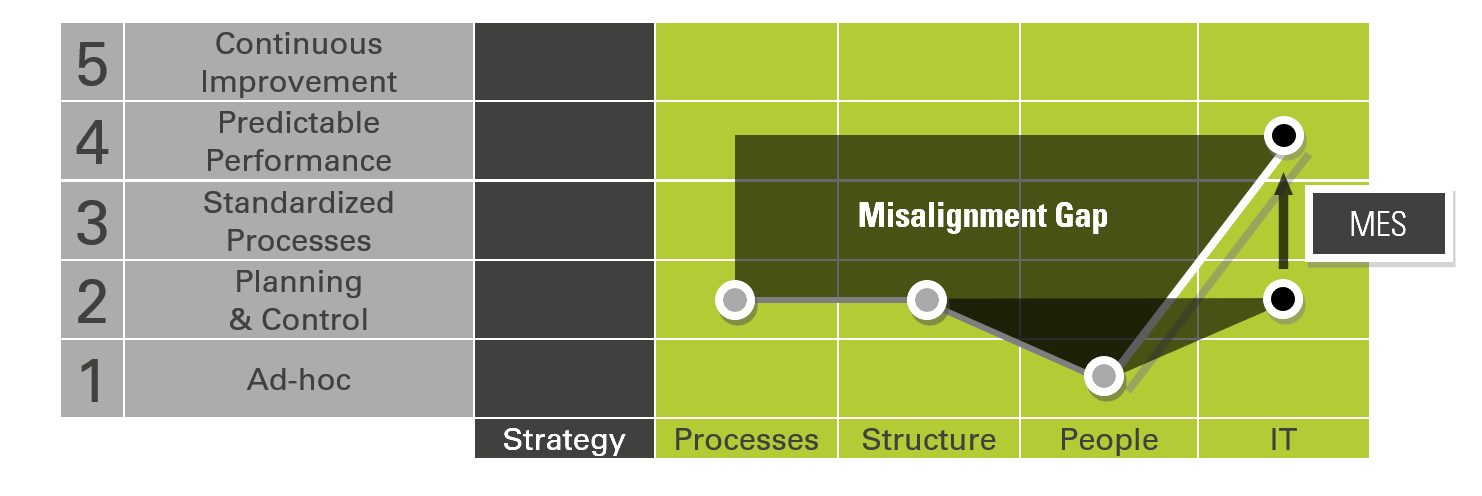

The graphic below illustrates the Manufacturing Maturity Model. The numbered rows on the left define the five levels of manufacturing maturity. Level 1 businesses have yet to bring digital technology very far into their operations. Data collection likely uses the machine’s standard sensors and there’s no plan for what data needs to be collected and, therefore, what sensors are needed. The data that is collected is only analyzed on an ad hoc basis and this analysis is reactive, rather than preventative (i.e., machine data is only accessed after a breakdown to find out what caused it).

The labeled columns at the bottom of the graphic show that a company's strategy is achieved by aligning its internal processes, management structure, people (culture and skills), and technology. The points on the graph illustrate the misalignment created when a company attempts to install an MES system capable of Level 4 performance, but their internal processes and management structure are only capable of operating at Level 2, and their plant-floor personnel have not had the training to operate above Level 1. To achieve full manufacturing maturity, each key area must be addressed as part of the digital journey.

First 5 Steps to Plant-Floor Digitization

As the graphic above illustrates, Industry 4.0 is not just built on technology; it’s most heavily built on the culture, training, and experience of the business’s staff, both at the production line and in the management suite. Without a culture that seeks to find efficiencies and is open to adopting new technologies, the business will struggle to overcome roadblocks along the way. If you are just beginning your digital journey, there are five practical steps to smooth your path.

First five projects to undertake:

- Digitization (systems and processes)

Identify the top three reports that add the most value to production. - Processes and integration

Identify which machines (if any) already have suitable sensors installed. A manufacturing business quite likely already has some operational sensors on the production line, it’s possible these can be better utilized to deliver fresh benefits that weren’t initially considered. For example, a production line might include standard sequence sensors which are used to trigger a cylinder moving a load from point A to B and back. By using the sensors to measure the time the cylinder took to move back and forth, a maintenance manager could be alerted to potential problems. Monitoring the data that is being produced by sensors that were already installed would help avoid machine downtime and improve OEE rates. A set of operational sensors thus become part of a predictive maintenance solution. - IT architecture

Implement internet connectivity and edge computing to enable machine-to-cloud connectivity across pilot production lines. A common scenario for many plant managers is that their older PLC is not equipped to draw value from IIoT and AI sensing technologies. A cost-effective alternative to purchasing a modern PLC is integrating an edge solution and specific sensors in your facility. An edge solution coupled with sensors can achieve equivalent or superior results at a fraction of the cost of standard PLCs. - Compliance, risk, and security

Identify the regulatory compliance requirements for your industry, analyze technical risks including data security, and ensure that your selected Industry 4.0 solution provider is capable and experienced in addressing them. - People and culture

Establish a lean manufacturing culture that understands the value that digital manufacturing solutions can add to the overall business and their day-to-day responsibilities and embraces the required changes to implement digital transformation programs across the organization.

CAT Squared is Here to Help

As experienced process specialists in the protein industry, we know first-hand the challenges of moving from one technological advancement to another while keeping production lines running and ensuring the business is meeting its goals. If you are experiencing challenges along your digital journey, please reach out to one of our technical resources at sales@catsquared.com.